CO2, Hydra Aquatics, Plant Maintenance, Regulators, Solution

Hydra Aquatics CO2 Regulator Safety Information and Installation Instructions

General CO2 Safety Message:

Keep out of reach of children.

Always wear safety protection for eyes.

CO2 is not toxic. However, it is odorless, colorless, tasteless, and can displace oxygen. A leak could result in a bad atmosphere if kept in a small space.

What are the health effects of carbon dioxide?

CO2 is considered to be minimally toxic by inhalation. The primary health effects caused by CO2 result from its behavior as a simple asphyxiant. A simple asphyxiant is a gas that reduces or displaces the normal oxygen in breathing air.

Symptoms of mild CO2 exposure may include headache and drowsiness. Rapid breathing, confusion, increased cardiac output, elevated blood pressure, and arrhythmias may occur at higher levels.

Breathing oxygen-depleted air caused by extreme CO2 concentrations can lead to death by suffocation.

CO2 discharge amounts for everyday aquarium use pose no health issue.

Typical tank sizes used for aquariums in average-sized rooms pose no health concerns, even if they leak. However, it is always best to test for leaks to ensure proper use.

Always ensure no leaks by using soapy water and/or pressure tests.

As compressed CO2 leaves a cylinder, it transforms from a liquid to a gas. The gas is -110˚F, which can cause instant tissue damage. It also generates a strong static discharge. If a tank is opened on an unregulated cylinder, shock may occur.

Do not install CO2 with wet hands. Do not touch white frost that may appear on the cylinder or equipment with bare hands.

Always test units after installation with soapy water suds for leaks. Slow leaks cannot be heard and will quickly empty a CO2 cylinder. The most likely place for a leak is the connection between the cylinder and regulating unit, and it is easily fixed by tightening if the gasket is in place.

Before Installation: Read all instructions!

• Do not use a wrench anywhere on the regulator except at the connection of the regulator and the CO2 cylinder. Using tools on any other part of the regulator will void the warranty.

• Never attempt to repair a regulator without consulting the manufacturer.

• For safety, always use protective eyewear when handling high pressure regulators.

• Important! The CO2 cylinder should be at ambient room temperature prior to installation.

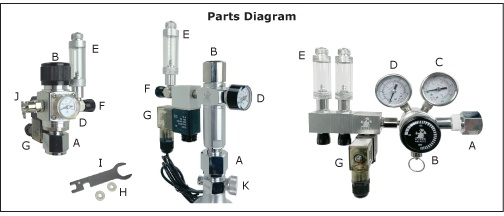

with Dual Stage & Dual Gauge

A. CO2 connection nut

B. Working pressure adjustment (some models do not have this)

C. High pressure CO2 cylinder pressure gauge. This will remain between 700-1000 psi for CO2. CO2 is a liquid and will go quickly to zero from these levels. It does not slowly decrease. Weight is the only accurate way to know the amount of CO2 in the tank.

D. Low pressure or working pressure

E. Bubble counter with integrated check valve (always use an inline check valve as well for added safety)

F. Needle valve for CO2 flow adjustment

G. Solenoid valve compatible with most pH

controllers and timers

H. Gasket or tank seal, also known as a washer

I. Tools

J. Pressure release safety dump valve

K. Cylinder Valve

How Regulators work

Hydra Aquatics CO2 Regulator Installation

- Vent the cylinder to remove debris from the cylinder. To do this safely, slowly open the valve for a second or two. Note! CO2 should never come in contact with the skin as it comes out at below freezing temperatures which can kill skin cells.

- Important! On adjustable models, verify the working pressure is at full “Decrease” by turning it in the decrease direction. This is counter clockwise, or to the left. Regulator damage may occur if the valve pressure is not turned down.

- Inspect the threads on the regulator. If the threads are not damaged in any way thread the regulator onto the cylinder making sure to use the gasket or seal provided. Tighten the connection securely with a wrench to avoid leaks.

Bubble Counter Installation (optional on some regulators)

- Locate the small o-ring that comes with the bubble counter. They are usually inside the unit or already installed. There are two types: large o-rings that go inside the cap of the bubble counter and a smaller one that goes on top of the nipple of the needle valve.

Do not over tighten or use tools for the installation of the bubble counter. Some needle valves are designed to rotate and swivel. This is normal. - Hold the clear tube of the bubble counter and unscrew the bubble counter top without the use of tools. Fill the clear counter tube 3/4 full with clean tap water.

- While holding the clear chamber, finger tighten the cap. Do not over tighten.

Important!

There is a rubber gasket or washer located in the bubble counter cap. Never remove it.

Important!

Always hold the clear tube of the bubble counter when removing the cap.

Important!

Never over-tighten the bubble counter onto the regulator.

Important!

Mineral oil is not recommended as it could contaminate regulators. Use RO/DI, tap or distilled water.

Universal Regulator Valve Assembly

On this model, the needle valve must be screwed into its open position. Screw the needle valve hand tight, then use the wrench included to seal. It has an O-ring. No teflon tape is needed.

Installation of Tubing, Check Valve, and Diffuser

- Carefully unscrew the tubing compression cap on top of the bubble counter. On regulators that do not come with regulator mounted bubble counters it is on the needle valve itself. Push the tubing through the cap and securely install the tubing onto the barb of the bubble counter or the needle valve if a regulator bubble counter is not being used.

Important! Use high grade CO2 rated tubing such as Hydra Aquatics or norprene tubing. - Important! To guarantee protection of the CO2 equipment and inline check valve, they should be installed after the regulator mounted bubble counter or the needle valve on the regulator. Install the valve close to the tank and before any diffusers or glass bubble counters. This will prevent any aquarium water from slowly creeping back from the aquarium.

Important! Make sure the check valve is mounted in the correct direction. The flow is toward the aquarium.

- Connect additional tubing to the check valve, then connect any bubble counter. Use precaution and heat tubing in hot water when connecting the glassware to prevent damage.

- Finally, connect the preferred CO2 diffuser using additional CO2 tubing remembering to heat the tubing in hot water as needed before installing onto glassware.

Open Cylinder Valve

- Close the needle valve by turning it clockwise until it is all the way off.

- Locate the working pressure regulator knob on the regulator if it is not a fixed outlet version. Confirm that it is set to its lowest (decrease) position by turning to the left or counter clockwise until it stops.

- Slowly open the cylinder valve counter clockwise one turn.

Adjust Working Regulator Pressure

Dial the working pressure knob until the regulator reaches the desired pressure. Always check the instructions on the chosen diffuser or reactor to see if it has specified pressure ratings.

10-20 psi for reactors

20-30 psi ceramic, glass, acrylic, stainless steel, and basic diffusers

30-40 psi high pressure atomizers, stainless steel, and some inline diffusers

40-60 psi some multi port outlet setups

Valves will be warm to the touch when operating in the on position or powered on.

Initially, test the unit by plugging it in without a timer.

Be sure and check any timer being used with the valve. Some timers do not provide clean power off/on and thus have a ghosting effect; therefore, the valve may not open properly.

Adjust The Bubble Rate

Open the needle valve slowly, turning it counterclockwise until the bubbles appear on the bubble counter. Fine tune the bubbles to 1-2 bubbles per second as a starting point.

Allow 5-30 seconds for pressure to stabilize between the settings. Monitor and adjust the bubble counter for the first few days as there is often a break in period for the regulators.

How To Test The System for Leaks

Always test the system for leaks after each installation.

Turn the needle valve off, then turn off the tank cylinder.

If any pressure is lost over 30 minutes, check for leaks between the needle valve and the tank.

Unplug the Solenoid Valve.

Prepare a solution of soapy water using dish detergent. Stir vigorously to create a foam.

Brush the foam on the cylinder nut and check for leaks working toward the needle valve. Look for slowly appearing or growing bubbles. Tighten any fitting as needed. Do not get foam on electrical connections. Dry thoroughly. Damage or electrical shock may occur if water is placed on electrical components not protected from water exposure.

Important! Leaks may appear very slowly, so pay close attention.

Removing to Refill

- Turn the cylinder valve off.

- Important! Never remove the regulator from the cylinder until you relieve the working pressure. Relieve the operating pressure by adjusting the knob; on adjustable models, turn entirely counterclockwise. This prevents damage to the low pressure gauge when you reinstall the regulator.

- Bleed any pressure from the regulator by opening the needle valve or pulling on the safety dump valve (supplied on some models).

- After the CO2 cylinder is filled, make sure it reaches ambient room temperature before reinstalling the regulator. Then follow the install instructions.

Warranty Information

In the rare case that the unit you have received is defective, Hydra Aquatics via Sevenports LLC provides a two-year limited warranty. Please take some time to register your new product and mail or email in the warranty form. Email [email protected] for any questions.

Hydra Aquatics warrants, to the original buyer, this regulator to be of the highest quality in material, craftsmanship and free of defects for a limited warranty of 5, 10 or 20 years (depending on the model) effective starting from the original date of purchase.

Under the limited warranty, Hydra Aquatics will replace or repair any product confirmed to be defective due to manufacturer flaws based on eligibility. This warranty extends only to personal use and does not include any product that has been used for commercial or rental purposes, or any other use in which this product is not intended. The warranty is voided if the product has been subjected to abuse, tampering, modification or repair done by owner, another person or by a non-qualified company. This warranty excludes damage due to normal wear and tear and is not warranted against moisture or water damage. This warranty does not include items that take normal wear such as the bubble counter, check valve, solenoid valve, or power supply for the valve. These items are covered for 1 year.

This warranty is non-transferable. Neither Hydra Aquatics nor Sevenports assumes any liability and is not responsible in any way for any loss, damage, or inconvenience caused by equipment failure or user error, negligence, abuse or use that is noncompliant with the safety instructions and warnings included.

All expressed and implied warranties are limited to the period of the original warranty.